WCC-570 Liquid Methyl

Tetrahydrophthalic Anhydride

(MeTHPA-Curing Agent for Epoxy Resin)

Features of WCC-570

liquid methyl tetrahydrophthalic

anhydride(C9H10O3) curing agent for epoxy

resin:

High purity,light colour:various desired

colour curing agent product for epoxy resin

can be propered directly or is formulated

using the anhydride.

Low viscosity : Good processability for

casting and potting.When casting,a large

amount of filler can be added to cured

compound,to properties is excellent.

Stable properties : Long pot life,low

solidification point,can be left at room

temperature for a long period of time.

Small volatility:Low toxicity,small heating

loss,as compared with amine hardeners,the

toxicity of WCC-570 is as low as 1/40 only.

It can obtain a superior quality of cured

compound.The cured article not only has

higher mechanical strength,but has better

properties of electric,heat resisting,and

anticorrosive as well.

WCC-570 has better

transparency,weatherability,and

potting-casting stability,especially is

suitable to be used for white

potting-casting compound,is an ideal

substitute curing agent for B-570(marketed

by Dainippon Ink and Chemicals,Inc.).

Please pay attention to this product should

avoid exposing to the sunlight,seal

tightly,keep at dry place during storage and

transport process.If take care of not

appropriate,in case of slight

precipitating,it can be used effectively

after only open is heated to about

140℃,without any effect on the original

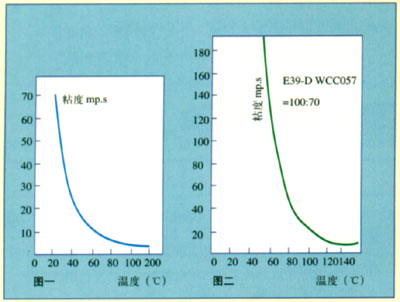

properties.Fig.1 Relationship

between temperature

Fig.2 Relationship between temperature

and viscosity of WCC-570 liquid and viscosity of mixed compound for

acid anhydride.

E-39-D epoxy resin with WCC-570 liquid acid anhydride.

Weight

ratio

User may select the type and usage amount of

the epoxy resin , accelerator , filler ,

toughner , and active diluent etc.,

according to product properties and

processing request based on the fellowing

principle.User may obtain an ideal formula

by performing the sample test.

⑴Epoxy resin

This curing agent is suitable for all type

of the epoxy resin,proper compounding ratio

of the hardener with the epoxy resin turned

on the equilibrium calculation of epoxy

equivalent.

The usage amount of WCC-570 to tyoe E epoxy

resin is a range of 50-80

phr.(abbreviate:phr=parts per hundred rubber

or resin).

⑵Accelerator

Frequently-used accelerator has benzyl

dimethylamine , DMP-30 , triethanolamine ,

2-ethyl-4-methylimidazole,and benzyl

imidezole etc,Usage amount is 0.2-2 phr.

⑶Filler

It is silica,mica,alumina,calcium

carbonate,talc,aluminium powder etc.When

using , it must be dry,added emount may be

20 phr.

⑷Other auxiliary agent

It may added toughner and active diluent

etc,when specific requiring.

Recommended cure processing condition

100 parts of the type E epoxy resin and 70

parts of WCC-570 mixed with 0.2-0.5 parts of

the above-mentioned accelerator

proportionately.

So long as at 60-70℃ deaearating,then at

100℃ remained for 2h, also at 120-150℃

remained for 4-10h,it could be accomplished.

At latter stage,temperature and time depend

on the volume of the curing compound and

processing condition.

Type E epoxy resin also can be cured with

the WCC-570 at lower temperature. It may

completely be cured in the range from 100℃

until low to 70℃.So long as properly

changing kind and amount of accelerator,it

can get a satisfactory result.

The company warmly deal the water,the

land,the air freight for the Chinese and

foreign basinessmap get empty to check.

We welcome to consulting and cooperating

with us.

Technical indexes Table

3

|

Model |

WCC-570 |

|

Item |

|

Appearance |

Pale yellow

clear liquid,no impurity |

|

Colour(Fe-Co

method) |

≤200# |

|

Viscosity

25℃,mpa.s |

≤45 |

|

Density

20℃,g/cm3 |

1.21±0.05 |

|

Content of

acid anhydride % |

≥40.5 |

|

Acid value

mgKOH/g |

660-685 |

|

Solidifying point ℃ |

≤-15 |

|

|