WCC-87 FLAME RETARDANT

EPOXY RESIN CASTING COMPOUND

WCC-87

flame retardant epoxy resin casting compound

is a new specific chemical industrial

materials for capacitor,composed of

composite low viscosity epoxy resin as base

resin,is added various modifiers.It has

excellent operative processing

properties,meeting the requirements of

casting metallized film capacitor and other

small part and component by

domestic,hand-made,and import equipment.Its

main properties indexes can reach the

properties indexes of EX 661(Sanyou resin

Co.,Ltd) and XN 1226(Ciba Co.,Ltd).

This compound has the

following characteristics:

⑴Excellent processing properties,low

viscosity.

⑵Long pot life.At 35℃,35g compounds(A+B),the

duration of time finishing the mixing to the

viscosity becoming twice as much as

origin—Pot life is more than 3.5hr.

⑶Low curing temperature,bright surface.

⑷Good mechanical,electrical,and thermal

properties.

⑸Low toxicity.

⑹Good flame resistance,in keeping with the

technical requirements stated in UL-94 on

V-1 grade.

⑺Two—package compound ,facilities for

use,long shelf life.

1.Liquid characterstics before curing

Table 1

|

No. |

Item |

Indexes |

|

1 |

Appearance |

A |

Pure black viscous liquid |

|

B |

Yellow-brown liquid |

|

A+B |

Black viscous liquid |

|

2 |

Viscosity(40℃,mPa.s) |

A |

4000-10000 |

|

B |

25-45 |

|

A+B |

400-1000 |

|

3 |

Density(25℃,g/cm3) |

A |

1.60-1.70 |

|

B |

1.19-1.21 |

|

A+B |

1.30-1.60 |

|

4 |

Gelation time(150℃,S) |

(A+B)* |

140 |

*(A+B):

A:B=100:30(W/W)

2.Cured product

characteristics Table 2

|

No. |

Item |

Index |

|

1 |

Water

absorption (23℃,24 hr,%) |

≤0.18 |

|

2 |

Flexural

strength(Mpa) |

≥65 |

|

3 |

Volume

resistivity(25℃ ohm-m) |

≥1013 |

|

4 |

Surface

resistivity(25℃,ohm) |

≥1013 |

|

5 |

Dielectric

strength(23℃,KV/mm) |

≥20 |

|

6 |

Dielectric

constant(25℃,1mHz) |

≤4.3 |

|

7 |

Volume

shrinkage(%) |

≤1 |

|

8 |

Dissipation

factor(25℃,1mHz,%) |

≤2 |

|

9 |

Coefficient of linear

expansion(1/℃) |

≤60×10-6 |

|

10 |

Glass transition temperature(℃) |

≥80 |

|

11 |

Flame

resistance |

FV-1 |

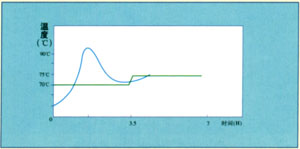

3.The

technological curve for WCC-87 flame

retardant epoxy resin casting compound.

⑴The relationship between temperature

and viscosity of major agent.

⑵The

viscosisty curve for mixture of major

agent and curing agent at 25℃.

⑶The

reactionary exothermal peak curve for

mixture of major agent and curing

agent.(100g)

4.Usage

process

⑴Before using,major agent is heated to

55℃,sufficiently stirred,in order that

partial precipitate is dispersed into resin.

⑵Vacuum deaerate for 1h to remove bubble.

⑶Casting:Adjust the measure to

appropriate,as soon as perform the casting

operation.

⑷Curing:Curring carry out under given curing

condition,open fan for heater,to internal

temperature is homogeneous.

5.Application note

⑴After every time usage operation finish,all

appliance should be cleaned using acetone or

alcohol,which contacted with resin.

⑵Remainder in using major agent and curing

agent(not mixed) should closely lidded with

cover.

⑶Operation environment should pay attention

to keep dry and ventilate.

This product is a non-flammable,non-explosive,and

non-corrosive goods.Flash point(COC)is more

than 100℃.

⑷Storage:At 25℃ dry place for 1 year. |

|