WCC-5217 FLAME

RETARDANT EPOXY RESIN POTTING COMPOUND

WCC-5217

model is a flame retardant epoxy resin

potting compound composed of polymer

resin,phosphonus fire-retardant,modified

fillers,additives and curing agents etc.It

is an ideal substitute for Hitachi Kasai

K.K.’s KE-5217(M)(S) model,is suited for

potting Fly Back Transformers of TV

sets,various electronic

and electric components by hand-made and/or

automatic continuous potting.

This compound has the following

characteristics:

⑴Low viscosity,good impregnation to coils.

⑵Not contains halide and stibide,has

self-quenching properties,non-corrosive to

coils.

⑶Excellent arc resistance and tracking

resistance.

⑷long shelf life of product,good application

properties(long pot life).

1.Technical specification of WCC-5217

|

Item |

Package |

WCC-5217 |

WCC-5217(M) |

Test method |

|

Appearance |

A |

radish brown |

radish brown |

by the eye |

|

B |

light yellow clear liquid |

by the eye |

|

Density (g/cm3)25℃ |

A |

1.62-1.70 |

1.62-1.69 |

GB1033-70 |

|

B |

1.20 |

1.20 |

GB1033-70 |

|

Viscosity (mPa.S)40℃ |

A |

10000-20000 |

10000-20000 |

GB2794-81 |

|

B |

20-45 |

20-45 |

GB2794-81 |

|

A+B |

400-800 |

400-800 |

GB2794-81 |

|

Ratio A/B(Wt.) |

100:30 |

100:28 |

|

|

Pot life (300g 33℃ h) |

> 4 |

> 5 |

NDJ-79 model Viscosimeter |

|

Gelation time (150℃)S |

120-180 |

200-260 |

LY234-83 |

|

Curing condition ℃/h |

75℃/2.5h+

110℃/2.5h |

80℃/4h+

100℃/4h |

|

2.Typical properties of

cured compound for the WCC-5217

|

Item |

WCC-5217 |

WCC-5217(M) |

Test method |

|

Heat distortion temperature

℃ |

100±5 |

95±5 |

GB1634-79 |

|

Hardness(Shore-D) |

90±5 |

90±5 |

GB2411-80 |

|

Glass transtion temperature

℃ |

≥95 |

≥90 |

TMA method |

|

Flexural

strength(kg/cm2) |

800 |

850 |

GB1042-79 |

|

Volume

resistivity(ohm-m)25℃ |

≥1013 |

≥1013 |

GB1410-78 |

|

Sulface

resistivity(ohm-r)25℃ |

≥1014 |

≥1014 |

GB1410-78 |

|

Dielectric

contant(1mHz 25℃) |

4.0 |

4.1 |

GB1409-78 |

|

Dielectric

loss tangent(%)1mHz25℃ |

0.8-1.2 |

1.0-1.3 |

GB1409-78 |

|

Dielectric

strength(KV/mm)25℃ |

≥25 |

≥25 |

GB1408-78 |

|

Volume

shrinkage(%) |

0.5 |

0.5 |

JB3961-85 |

|

Thermal decompose temperature

℃ |

> 240 |

> 240 |

DSC method |

|

Water

absorptivity(%) 23℃ 24hr |

≤0.15 |

≤0.15 |

GB1034-86 |

|

Arc

resistance(25℃ 12.5KV,S) |

> 180 |

> 180 |

GB1411-78 |

|

Flame-retardancy |

FV-0 |

FV-0 |

GB4609-84 |

|

Linear expansion(Tg,1/℃) |

≤45×10-6 |

≤45×10-6 |

GB1036-70 |

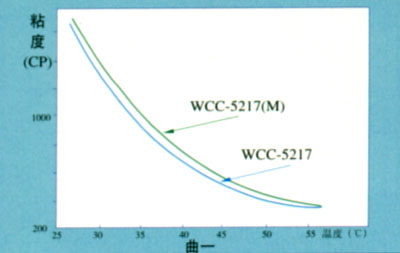

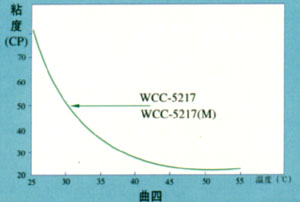

3.WCC-5217 WCC-5217(M) A+B

mixed material’s temperature-viscosity

relationship curve

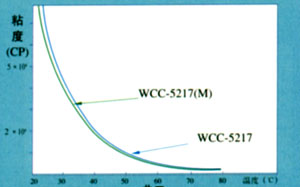

WCC-5217

WCC-5217(M) The

relationship between temperature and

viscosity of major agent(A package)

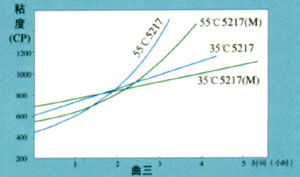

WCC-5217 WCC-5217(M)

Isothermal curve of A+B mixed material

WCC-5217 WCC-5217(M)

The relationship between curing

agent-viscosity

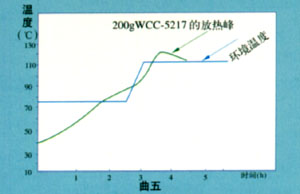

WCC-5217 WCC-5217(M)

Exothermal peak curve of A+B mixed

material(200g)

4.Usage

process

Before potting,package Aand B of the

WCC-5217 model must respectively vacuum

deaearated,then should be mixed by high

speed stirring.WCC-5217(M) is suitable for

deaearated potting process or hand-made

potting process after package A and B are

mixed.

⑴Component A:vacuum deaearate with stirring

for 4-6 h at 60℃±5℃ and 1-3 mmHg of absolute

pressure;

Component B:vacuum deaearate with stirring

for 3-4 h at 35-40℃ and 1-3 mmHg of absolute

pressure.

⑵Adjust the ratio of component A and

component B after vacuum deaearation to

100:30(WCC-5217) and to 100:28

(WCC-5217(M))(by weight)respectively.

⑶Preheat the devices to be potted at 90-100℃

for 2-6 h.

⑷Put the devices preheated into a vacuum

casting-potting machine and wherein perform

the potting operation at 5-8 mmHg pressure.

⑸Put the potted devices into a curing oven

and where in cure them under given curing

condition.

5.Application note:

⑴The fillers in component A stocked for long

time tend to precipitate,therefore it must

pay attention to homogeneously agitate

before use.

⑵The curing agent tend to crystallize at low

temperature in winter,it must heat them to

70-80℃ in the use (fully solubilized),having

no influence on quality.

⑶The curing agents very easy to absorpt

humidity tend to form precipitate which can

reduce the shelf-life and have influence

upon quality.It must be used up as soon as

possible,if once it is unsealed,and pay

attention to closely cover the rest.

Storage:25℃ in a dry place for 1 year.

Transport:

As ordinary chemicals,because no fire-and

explosion-hazardous. |

|