WCC-5203A FLAME RETARDANT

EPOXY RESIN POTTING COMPOUND

WCC-5203A is a flame retardant epoxy

resin potting compound for fly-back transformer

of colour TV sets.The product is a two-package

potting compounds composed of flame retardant

epoxy resin and acid anhydride curing agent

etc. may be design and supplied in terms

of customer’s requirements at home and abroad.It

has similar technical properties and application

procedures to the flame retardant epoxy

resin casting compound KE-5203 issue from

Japan’s Hitachi Kasai K.K.,and appropriate

to use on introduce line from elsewhere

of fly-transformer of colour TV sets for

automatic and continuous vacuum casting-potting.

This compound has the following characteristics:

⑴Curing time is shorter.Total curing time

only is 5 hours.

⑵Low viscosity,good impregnation to coils.

⑶Smaller dielectric constant.Excellent

electrical properties.

⑷Excellent flame retardant property arrived

at V-0 grade determined by the standard

UL-94.

⑸Without any corrosion on polyester enameied

wire,potted product has higher reliability.

Mixing ratio and curing condition:

| Type |

WCC-5203A |

| Major agent(Epoxy resin) |

5203A |

| Curing agent(Anhydrides) |

5203B |

| Mixing ratio(by weight) |

A |

100 |

| B |

30 |

| Curing condition ℃/h |

75/2.5+0.5h

rising temp.+105/2.5h |

Typical properties of WCC-5203A before

curing:

|

Item |

Package |

Unit |

WCC-5203A |

Test Method |

|

Appearance |

|

|

White |

By the eye |

|

Viscosity |

A |

40℃ mpa.s |

1.1-1.5×104 |

GB2791-81 |

|

|

B |

40℃ mpa.s |

20-25 |

Idem |

|

|

A+B |

40℃ mpa.s |

450-700 |

Idem |

|

Density |

A |

25℃ g/cm3 |

1.60-1.80 |

GB1033-86 |

|

|

B |

25℃ g/cm3 |

1.10-1.30 |

Idem |

|

Gelation time |

150℃,s |

120-160 |

LY234-83 |

|

Pot life* |

35℃,h |

>4 |

|

*with double initial

viscosity

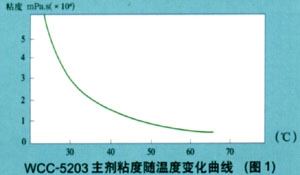

WCC-5203 A package viscosity

characteristic:

Fig.1 The relationship between temperature

and viscosity of the A package.

WCC-5203 B package viscosity

characteristic:

Fig.2 The relationship between temperature

and viscosity of the B package.

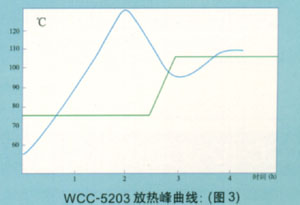

WCC-5203 A exothermal indication curve:

Fig.3 Exothermal

Indication Curve of WCC-5203 A

Typical properties of cured compound for

the WCC-5203A

Technical Specification of the WCC-5203A

cured compound

|

Item |

Condition |

Unit |

WCC-5203A |

Test Method |

|

Hardness |

25℃ |

Shore-D |

90 |

GB2411-80 |

|

Volume resistivity |

25℃ |

ohm-m |

4.5×1013 |

GB1410-78 |

|

Volume resistivity |

100℃ |

ohm-m |

2.0×1012 |

GB1410-78 |

|

Dieledtric Constant |

25℃ |

|

≤3.8 |

GB1409-78 |

|

Dieledtric Constant |

100℃ |

|

≤4.2 |

GB1409-78 |

|

Dielectric loss tangent |

25℃ |

% |

0.7-0.9 |

GB1409-78 |

|

Dielectric loss tangent |

100℃ |

% |

1.1-1.2 |

GB1409-78 |

|

Dielectric Strength |

25℃ |

KV/mm |

>25 |

GB1408-78 |

|

Arc resistance |

25℃ |

12.5KV,s |

>120 |

GB1411-78 |

|

HDT |

|

℃ |

≥105 |

GB1634-79 |

|

Tg |

|

℃ |

≥108 |

TMA Method |

|

Linear Expansion |

Tg |

mm/mm/℃ |

4.5×10-5 |

GB1036-70 |

|

Flexural Strength |

23℃ |

Mpa |

≥81 |

GB1042-79 |

|

Flexural Modulus |

23℃ |

Mpa |

6620 |

GB9341-88 |

|

Tensile Strength |

23℃ |

Mpa |

≥49 |

GB1040-79 |

|

Thermal Conductivity |

|

Cal/cm ℃ s |

9.0×10-4 |

GB3399-82 |

|

Impact Strength |

|

KJ/m2 |

≥13 |

GB1043-79 |

|

Thermal Decompose Temp. |

|

℃ |

>250 |

DSC Method |

|

Surface Resistivity |

25℃ |

Ω |

≥1014 |

GB1410-78 |

|

Water Absorptivity |

23℃ 24h |

% |

<0.1 |

GB1034-86 |

|

Flame-retardancy |

UL 94 |

|

V-0 |

GB4609-84 |

Wet resistance of The

WCC-5203 A

Boiling test characteristic:

|

Item |

|

Unit |

WCC-5203A |

|

Volume Resistivity |

Initial value |

ohm-m |

4.5×1013 |

|

After boiling* |

ohm-m |

2.0×1012 |

|

Dielectric Constant ε 1MHz |

Initial value |

|

3.8 |

|

After boiling |

|

4.2 |

|

Dielectric loss 1MHz tangent δ |

Initial value |

% |

0.8 |

|

After boiling |

% |

1.2 |

*Boiling Condition:After

100℃ boiling water/4h+ running water immerse

/ 16h,the data may be determined.

Safety of the WCC-5203A

|

|

Major components |

Safety |

|

WCC-5203A |

Epoxy resin, Fillers, Flame –retardant,Additives |

Slightly irritating to the skin |

|

WCC-5203B |

Anhydride,Acceleratot |

Certainly irritating to the skin |

|

A+B |

|

Slightly irritation |

Storage condition:

At storage,no opening package drum.Should

storage at lower than 35℃, approximately 70%

RH,avoid light and ventilate,and must keep

these materials far away from the fire

source.Storage time do not go beyond range

of 0.5-1 year.

Usage Process:

Before casting-potting,package A and package

B of the WCC-5203 A must respectively

vacuum deaerated,should be mixed.The

casting-potting operation of the material

can perform after mixing and re-deaerating.Recommend

usage process as follows:

1.Component A:vacuum deaerate with stirring

for 4-6h at 60℃±5℃ and 1-3 mmHg of absolute

pressure;

Component B:vacuum deaerate with stirring

for 3-4h at 38-40℃ and 1-3mmHg of absolute

pressure;

2.Adjust the ratio of component A and

Component B after vacuum deaeration to

100:30(by weight);

3.Preheat the devices to be cast-potted at

90-100℃ for 2h;

4.Put the devices preheated into a vacuum

casting-potting machine and wherein perform

the casting-potting operation at 5-8 mmHg of

pressure;

5.Put the cast-potted devices into a curing

oven and wherein cure them under given

curing condition;

6.Above process may be adjust with according

to various vacuum casting-potting machine.

Application note:

1.The fillers of component A stocked for

long tend to precipitate,therefore it must

pay attention to homogeneously agitate

before use.

2.The curing agent tend to crystallize at

low temperature in winter,it must heat them

to 70-80℃ in the use(fully

solubilized),having no influence on quality.

3.The curing agents very easy to absorpt

humidity tend to form precipitate which can

reduce the shelf-life and have influence

upon quality.It must be used up as soon as

possible,if once it is unsealed,and pay

attention to closely cover the rest.

Transport:

As ordinary chemicals,because no fire-and

explosion-hazardous. |

|